Most parcel and LTL shippers identify fast order fulfillment (fewer than two days) as their number one strategic focus, but a common problem affecting these shippers is their ability to actually implement the various optimization opportunities available to them. Being able to proactively identify and prepare for these constraints is the key to implementing an optimization strategy and gaining the maximum return on your investments.

Most optimization strategies can be grouped by the strain they place on the existing systems of a parcel network. These barriers to optimization are commonly felt in either the network’s IT or physical infrastructure. They usually appear as either a limited set of order management systems or as a physical infrastructure which will need to be redesigned or replaced to accommodate new volumes and directional capacities. Both of these types of changes can involve significant cost and time investments which can quickly eat away any savings derived from these strategies.

The large majority of companies today will make use of a distributed order management system to ship their packages in the most cost-effective and time-efficient way possible. New optimization strategies can be hindered by these existing systems’ limited capabilities. A typical management system will either be a commercially available product or a legacy system designed in-house. Upgrading the capabilities of these systems can involve large costs by way of upgrading the subscribed version or through new code implementation. In the case of the latter, this constraint can be further exacerbated by any IT development currently in the works. The main variables involved in shipping a package will generally be optimized by the information strategically provided to these management systems. That is, carrier and service optimization will revolve around the systems’ rate shop capabilities while DIM and box optimizations will be primarily driven by a company’s dimensioning system. Any attempts at accessorial avoidance will essentially be a combination of all these things.

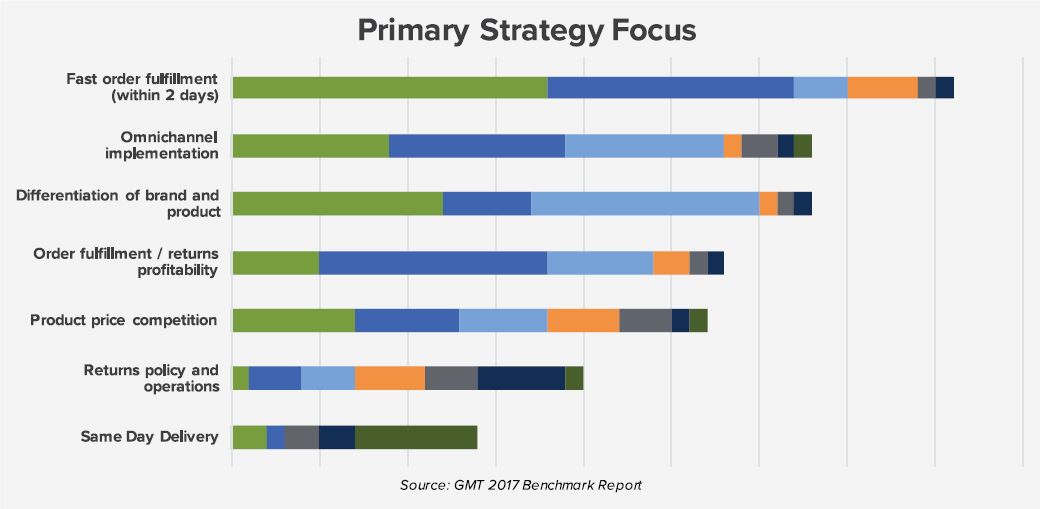

Optimization strategies will also have an impact on the way companies move and store their inventory. For example, companies will sometimes seek to optimally source certain high-demand products in an attempt to reduce the average distance traveled. This seems to be a simple case of moving a thing from here to there (sound familiar?), but in reality something as simple as the number of available racks can hinder the implementation of this cost saving solution. In fact, according to Green Mountain Technology’s latest Benchmark Report, 50% of respondents plan to increase their company-owned distribution space. Simultaneously, the use of dropship vendors has almost doubled from five percent to nine percent since last year, and DC usage dropped that same amount in that same time period. So while it is obviously more desirable to have complete control of that square footage, the outsourcing of specific subsets of a parcel network can sometimes be more efficient. Besides getting the products in, another hindrance can be a warehouse's ability to get products out. The number of dock doors and the warehouse conveyer systems are examples of physical systems which may need to be upgraded or redesigned in order to handle differing trailer capacities and the faster fulfillment times of certain express services.

Finally, one of the most common hindrances for any company’s growth is an aversion to change and the growing pains that come with it. Change is scary because of the uncertainty that comes with it, but the number one way to combat uncertainty is through being prepared. That preparedness revolves around knowing the weaknesses of your network, knowing how you plan to fix them, and most importantly knowing how to put those plans into action.

William Cordell is a Strategic Solution Engineer at Green Mountain Technology, a Parcel Spend Management provider for shippers with over 10 million parcels per year. In this role, William partners with customers to provide our strategic Parcel Spend Management solutions – Network Optimization, Spend Analytics, and Contract Management. William has a Bachelor of Science and a Master of Science Degree in Applied Mathematics from Mississippi State University.