This article originally appeared in the March/April issue of PARCEL.

Supply chain design — if it wasn’t important before, it surely is now. Online selling’s dramatic growth has energized supply chain design, bringing with it a lot of questions. How many warehouses should I have? Where should they be located? What should I stock in them? How will my supply chain help me sell more? The benefits of e-commerce, principally fast delivery, ripple through the broader economy; even B2B consumers ask, “Why can’t you deliver it like Amazon?” We’re spoiled!

All material things begin and end in “Mother Earth.” In between, they’re in a supply chain. Supply chains are everywhere. For an organization designing or just improving their supply chain, there are two dimensions to wrestle with — service and cost. Providing service to customers is the sole purpose of a supply chain. Because you can spend your way to virtually any service level you wish, cost is the other core dimension critical to any well-designed supply chain. Each of these dimensions has components.

SERVICE AND MARKET SHARE

Many believe the service dimension can be sorted into several components. They cite lead-time, availability or fill, resolving problems, returns, and so on. Interestingly these can all be collapsed into one component — lead-time. If your supply chain minimizes the time it takes your customers to get what they want, you’ll have all the service bases covered.

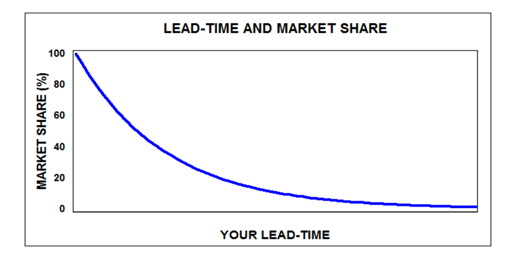

So significant is your lead-time that it drives market share. Everything else being equal, the market share-lead-time relationship looks like this:

This relationship stems from the recognition that one day out of a long lead-time, say 20 days, is minor (five percent). But a day out of a two-day lead-time is 50%. That difference gets noticed by shoppers and drives the buying decision. So lead-times, always important, are more critical in short lead-time markets; all the more reason to know your competitors and design your supply chain to provide even shorter lead-times than theirs.

LEAD-TIME OPTIMAL WAREHOUSE NETWORKS

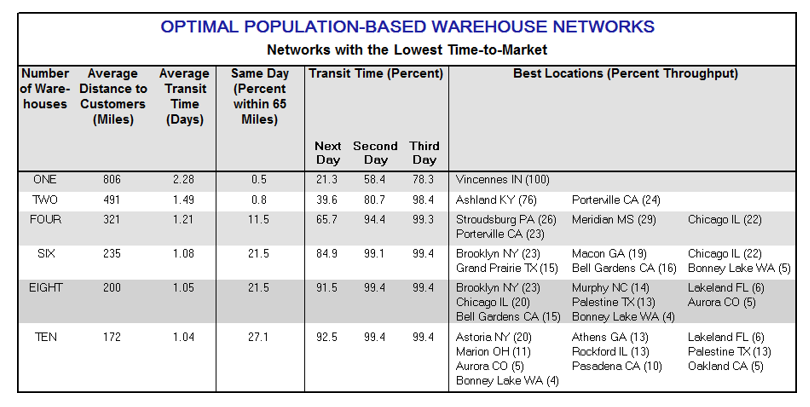

You can actually design a supply chain to minimize the lead-time provided to your customers. It’s not a bad idea, so let’s do it. Take the US population as if they or some uniform subset of the population were your customers. Let’s design a warehouse network to minimize the lead-time to get to these customers. Here’s the result:

This means that if you put a single warehouse in any place other than Vincennes, IN, your average transit lead-time will be greater than 2.28 days. If you put two warehouses in any places other than Ashland, KY and Porterville, CA, your average distance to customers will be more than 491 miles.

These are service-based networks. They have been specified on the basis of their distance (and, consequently, their lead-time) to customers.

COST OPTIMAL WAREHOUSE NETWORKS

At a high level, the critical components of the cost dimension of supply chains are three: transportation, warehousing, and inventory. That’s the normal importance sequence too. Let’s look at all three.

Transportation

Transportation costs often decrease as warehouses are added to a network. This is due to the generality that transportation costs decrease as distances decrease, and adding warehouses to a network decreases distances from them to customers. A regional warehouse has products closer to its customers, which diminishes the average distances in the whole network.

Of course you have to pay the freight to get material to the regional warehouse. This can often be financed from the savings in the shorter outbound distances to customers. It’s why efficient inbound freight (ocean, rail, LTL) coupled with less efficient outbound (LTL, parcel, currier) augers for multi-warehouse networks.

Yet this effect has limits. It doesn’t work within small territories — inside a parcel zone, transportation costs are the same.

Warehousing

If you consider that variable warehousing costs — such as receiving, put away and picking — have to be done regardless of the number of warehouses, then you’re left with fixed warehousing costs that change with the number of warehouses. These are nominally costs for docks and staging areas, management, systems, and technology. Yes, variable labor costs depend on the region of the country but they can vary even more between the relatively nearby urban and rural areas than across widely separated regions. So addressing how close your warehouse is to an urban center is often critical.

Inventory

Finally, supply chains have inventories. If they are in one warehouse, they can’t be in the wrong warehouse! Storing inventory in multiple regional warehouses leaves you open to more stock-outs and more inventory needed to cover them. Dividing up the country into multiple regions makes slower movers out of every item. Slower movers are harder to forecast; their demand is more variable. This variability requires proportionately more safety stock to achieve the same availability levels. Inventory increases.

OPTIMIZING

So we have our two dimensions, service and cost. What’s the connection between them and how do we “optimize” our supply chain?

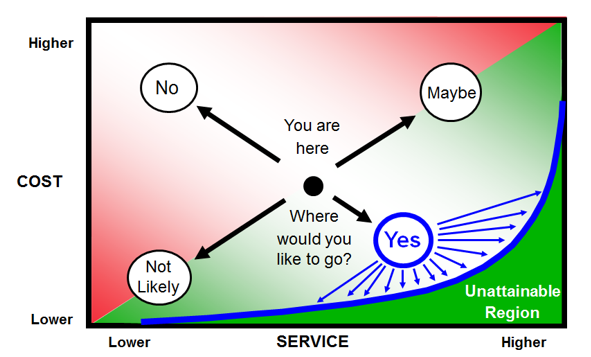

Here’s the connection:

In this illustration, you cannot be in the lower right corner; it takes some inventory, some cost, to provide high service. You cannot be very close to customers without warehouses. So between where you are – the black dot – and where you cannot be – the lower right corner – there has to be a barrier – the blue line – that you can’t cross. Options on this line are optimal; the highest possible service for a given cost and the lowest possible cost for a given service. Optimization means being on the blue line.

The actual optimization process — constructing the blue line — can be done by sorting through all the options, at least implicitly. There are many software tools useful in performing the calculations. They come with a variety of price tags; some in the six figures and some free.

Deciding where along the blue line to target generally requires understanding where competitors are positioned and how customers respond to your collective service offerings. As service becomes more of the buying criteria, you’ll need to move up the curve. If cost minimization is your strategy, you will move toward the left. Just understand that the dependence between these dimensions — optimality or being on the blue line — means there’s a tight trade-off between service and cost. Be consoled, however, by that trade-off being the best one possible.

Designing optimal supply chains has become a necessity in our fast, highly served economy. The benefits are dramatic. We need only look at the performance of the companies we buy from while sitting at our desks for crystal clear proof.

Terry Harris is Managing Partner, Chicago Consulting and frequent speaker at the PARCEL Forum. He can be reached at terry@chicago-consulting.com

![GettyImages-911045162-[Converted]](https://cms-static.wehaacdn.com/parcelindustry-com/images/GettyImages-911045162--Converted-.2298.widea.0.jpg)